|

|

|

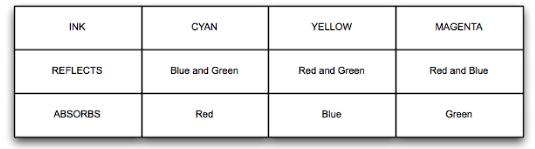

Monitors, Printers and ColourHow monitors display a pictureMonitors display a picture by effectively emitting combinations of red, green, and blue light from hundreds of thousands of triads of red, green, and blue emitters. In former times, the emitters were made from phosphorescent materials that glowed red, green, or blue when stimulated by a 'cathode ray' (beam of electrons) inside a tube. These days the emitters are LEDs (light emitting diodes) fronted by red, green, or blue filters: kind of like the inverse of the camera sensor, but different filters, and different chemistry and physics are involved! Think about zooming in on just one coloured spot inside an image displayed on your computer's monitor. The combined light emitted from each triad represents the colour and intensity of light at that spot in the image. Each triad is sent three numbers, each number between 0 and 255 representing the proportion of red, green or blue light to be emitted by that triad. An image file consisting of hundreds of thousands of number triples, one for each triad of emitters, enables the monitor to display an image. The complete set of colours (and associated number triples) that the monitor can display is a device-dependent colour space. How printers produce a photographUnlike a monitor, paper is not a light emitter (you can’t see a photograph in the pitch dark.) Ink-covered paper reflects some of the light that shines on it. You see different colours at different points in a print because the paper-and-ink absorbs some of the light that falls on it, and reflects the rest. The colours you see are the result of the combinations of red, green, and blue light that are reflected from the ink-coated paper.

Yellow ink absorbs blue light but reflects red and green, while magenta ink absorbs green light and reflects red and blue. Black ink absorbs all colours and reflects nothing. To make a red dot in a scene, the ink would reflect only red light: it would need to absorb all green and blue. Equal quantities of yellow and mageneta inks would absorb all green and blue and reflect only red. An ideal printer would lay combinations of cyan, yellow, magenta ink at each ‘dot’ in a print to reflect the appropriate combinations of red, green, and blue that make up the observed colour and tonality of the dot. To make a picture on such a printer, we would send to the printer driver, a file full of triples of numbers that tell it the amounts of red, green, and blue that will need to be reflected to make the correct colour and tonality at each dot in the image. The printer driver would convert that information into instructions telling the printer what combinations of cyan, yellow, and magenta ink to squirt at each dot. If this sounds hard enough, real printers are more complicated because inks themselves cannot be made perfectly cyan, yellow or magenta. Most printers mix other colours of ink to better achieve the task of reflecting the appropriate combination of red, green and blue. The complete set of colours, together with the RGB number triples associated with each colour, that the printer can produce is a device-dependent colour space. The actual colours associated with a number triple sent to a monitor or to a printer, are determined by using sophisticated measuring equipment, in the process of 'profiling' the monitor and 'profiling' the printer. |

|||

Colour Management |

|||

|

Monitors, printers, and colour |

|||

The Colour Match Challenge |

|||

|

|

|||

How the Challenge is met |

|||

|

Translating colours: ICC Profile |

|||

Theoretically, cyan ink absorbs red light and reflects green and blue.

Theoretically, cyan ink absorbs red light and reflects green and blue.